3D printing has had a spot within the bike business for a few years now. Currently although, it appears to have actually exploded. A part of that’s how rather more accessible additive manufacturing is now, with Ender 3s going for $99 at Microcenter (with a coupon). On the opposite aspect of issues, 3D printing expertise is quickly enhancing making it simpler than ever to create speedy prototypes of complicated shapes.

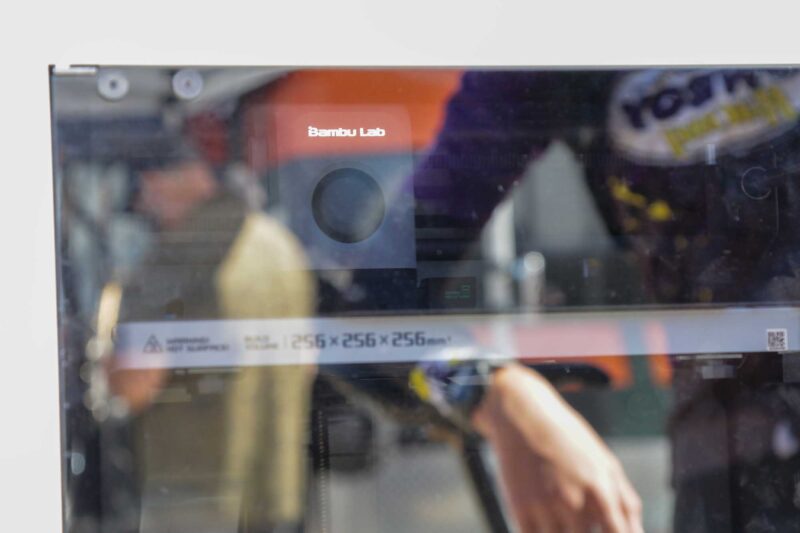

Making the most of the newer super-fast Bambu X1C printer, OutsideBrendan was on the Marin Cycles sales space printing on-site. These attending the present might snag certainly one of his BananAdapters whereas testing a few of his artistic chainring designs or a Lego saddle?

Selle Italia

Talking of saddles, 3D printing is changing into much more frequent to create performance-oriented fashions. Using 3D printing permits firms like Selle Italia to construct up the padding utilizing lattice building that may be progressively tuned – that means the again of the saddle could be made extra agency than the entrance whenever you want extra cushion.

Above is the brand new Novus Evo saddle which is 3D printed utilizing Selle Italia’s personal 3D printers. The covers are printed two at a time and take a number of hours to finish, and are then glued to the bottom. The Novus Evo makes use of its personal sample for the quilt, and isn’t accessible on the market simply but. When it’s, it will likely be provided in a single measurement with carbon or ti rails and is totally made in Italy.

Identified for his or her extremely exact machining, Abbey Bike Instruments was additionally displaying off some 3D-printed components. Should you personal a Crombie instrument, chain whip, HAG, or Decade chain instrument and also you’d like a 3D-printed instrument hanger for pegboard, you’re in luck (click on hyperlink for every instrument for the corresponding holder). Abbey will probably be providing these free of charge, so long as you pay delivery. They’re additionally taking suggestions on the designs in case you assume there’s a means to enhance them.

Abbey can also be promoting their new PreHag instrument which can also be 3D-Printed. What’s a PreHag? Consider it as a precursor instrument to make use of of the HAG (Hanger Alignment Guage). The PreHag matches onto the biggest cassette cog, and acts as a visible gauge to see if the derailleur cage is roughly in parallel with the cassette. Basically it’s a visible support that can let you realize if it is advisable to bust out the HAG for some hanger alignment (assuming you’re nonetheless working a conventional derailleur hanger).

Elevation Wheel Firm

Chris Murray of Elevation Wheel Firm has been producing instruments for some time now, together with quite a few 3D printed gadgets like their nipple shuffle field. The time-saving field lets you dump nipples in for a wheel construct, give it a shake, they usually all find yourself pointing down so you’ll be able to load them up on a nipple lacing instrument and construct your wheel. They even had miniature variations made into keychains on the present.

Different 3D printed gadgets embody a hub press adapter for the wheel spoke stressor, wrenches for his or her spoke stress calibration instrument, and substitute jaw pads for restore stands.

Chris additionally put the printer to work printing out show gadgets for Twisted Spoke CBD who was sharing the sales space.

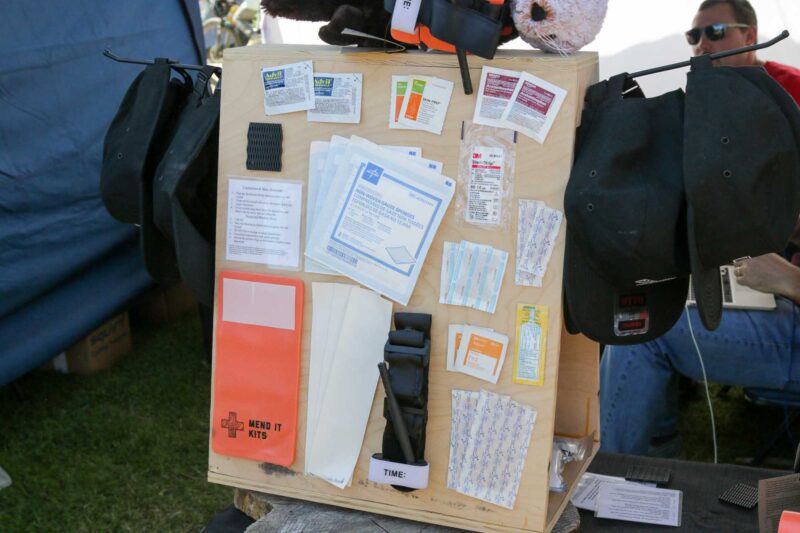

Mend It Kits

Transferring from instruments in your bike to instruments in your physique, Mend It Kits are an attention-grabbing tackle the primary support package that you simply strap to your bike. All the things proven on the board is included with the package, together with…

…these 3D-printed finger splints. The printed design makes them versatile in a single route, however not the opposite. Place it round your finger, trim to measurement if wanted, and tape it up.

KAV Helmets

With regards to 3D-printed helmets, we’ve been following together with the KAV improvement for a number of years now. Each time we see them, the helmets function spectacular enhancements, with fast design modifications one of many principal advantages of 3D-printing. Not solely is KAV getting ready to launch completely different coloration helmets later this yr, however the helmet itself has seen updates together with a brand new brow-liner sweat-management pad. You’ll additionally discover bigger entrance vents for higher airflow and improved spring-loaded pads with extra snug floor supplies.

KAV will start to supply stable coloration helmets in Q3 of 2023, adopted by their customized Shade Exploration Program which is able to permit riders to pick completely different coloration panels.

SRAM Blackbox

We don’t have a lot information on this, however these look like prototype SRAM brakes with 3D-printed Blackbox shields. Are the shields there to cover one thing from view? Are they to guard the brake, or the rider from the brake? Maybe some form of cooling machine?

Regardless of the case, they have been on Kyle Strait’s Vitus Dominer DH bike which additionally had some prototype tires from Kenda.

From parts to border parts, the comparatively new customized bike model Neuhaus Metallic Works is utilizing 3D printing to create ‘lugs’ and different body components for his or her metal and titanium builds.

The Neuhaus frames use 4 completely different 3D-printed items on the entire construct. The seat publish cluster is printed so it wraps across the seat tube permitting for higher and stronger welds and higher body alignment. The chainstay yoke is printed to supply probably the most tire clearance and weld floor to the underside bracket. There’s additionally a water bottle bracket that lets you use a full-size water bottle bolt with out interfering with the dropper publish insertion. Lastly, the dropper port plug is printed with an insert that holds the cable in place and prevents it from rattling.

Every bike is handmade by Nick Neuhaus in Marin, California, and is out there because the Hummingbird downcountry mannequin or the Solstice 29 aggressive path bike.

Rise Bikes

Additionally utilizing 3D printed titanium is the Grizzly fats bike from Rise Bikes. This magnificence makes use of a 3D-printed head tube, dropouts, and chainstay yoke made out of 6Al/4V Titanium by Selective Laser Melting. The 3d printed chainstay yoke permits for 26 x 4.8″ or 27.5 x 4.3″ tires on 85mm rims whereas retaining chainstay size to a powerful 434mm.

Sage Cycles

Sage Cycles can also be utilizing 3D printing to develop a brand new dropout that’s formed to seem like the Tron Lightcycles’ wheels, the place the axle appears to be like just like the hub from the unique film, however the form is from the sequel. The dropouts are designed particularly for the Robert Axle Challenge via axle.

Revel Bikes

I misplaced most of my photographs for the Revel Rodeo, so I had Adam Miller ship me a snap from his sales space. This roundup wouldn’t be full with out the prototype Revel Rodeo – a 3D-printed thermoplastic downhill mountain bike. Reasonably than simply printing a number of parts of the body, the Rodeo body is printed with the principle triangle cut up into two halves, after which bonded collectively. Merely a design train for now, the Rodeo might level towards the way forward for 3D-printed manufacturing within the bike business.

Silca

We’ve seen quite a lot of 3D-printed merchandise from Silca, and this chainstay above is solely a proof of idea. Are many (any?) model 3D printing a whole chainstay meeting? No, however you possibly can…

Hunt Wheels

A number of these merchandise are precise manufacturing gadgets which were 3D printed, however additive manufacturing is simply as, if no more helpful for speedy prototyping. Right here, Hunt reveals us some rim sections from an upcoming wheel together with a jig they designed to assist check spoke pull-through power of the edges.

Outbound Lighting

Alongside those self same strains, Outbound Lighting has been utilizing its new Discussion board Labs Fuse SLS printer to develop its subsequent headlight. A lot of the hobbyist printers together with the Bambu X1C above use FDM (Fused Deposition Modeling) printers, however some just like the one Outbound is utilizing depend on SLS (Selective Laser Sintering). These printers can create extremely exact and complex fashions with little or no post-processing.

The sunshine above is a brand new MTB mild coming this fall, and all of the printed items could possibly be snapped collectively to create the ultimate kind.